On January 8, 2026, the 6th Session (2nd Meeting) of Foshan Ceramic Industry Association successfully concluded at Huaxia Pearl Hotel. As a technology enabler for intelligent manufacturing in the ceramic industry, DPI Cretaprint was invited to attend and deliver a keynote speech themed "New Technologies in the Ceramic Industry". Centering on the comprehensive product matrix built around "full-process collaboration + digital glazing + digital printing" and the 6th-generation equipment upgrade plan, DPI explored new paths for intelligent industrial upgrading together with industry partners.

This annual conference upheld the authoritative and professional legacy of Foshan's ceramic industry events, bringing together key players across the entire industrial chain. Leaders from top ceramic enterprises such as Guangdong Hongyu Group, New Pearl Group, Mona Lisa Group, and Dongpeng Holdings, along with industry experts and representatives from major media outlets—over 100 attendees in total—gathered to conduct in-depth discussions and exchanges around two core topics: technological innovation and industrial upgrading.

President of the Foshan Ceramic Industry Association, Dr. Yin Hong

With "reviewing the past, analyzing trends, and driving technological innovation" as its central theme, the conference covered key dimensions of industry development. Dr. Yin Hong, President of Foshan Ceramic Industry Association, delivered a keynote speech titled "Analysis Report on Industry Situation and Development Trends". He provided an in-depth analysis of the current development status, market opportunities, and challenges of the ceramic industry, offering valuable strategic guidance for the transformation and development of enterprises present and further clarifying a clear direction for the high-quality development of the industry.

President & GM of DPI, Mr. Tao Cheng

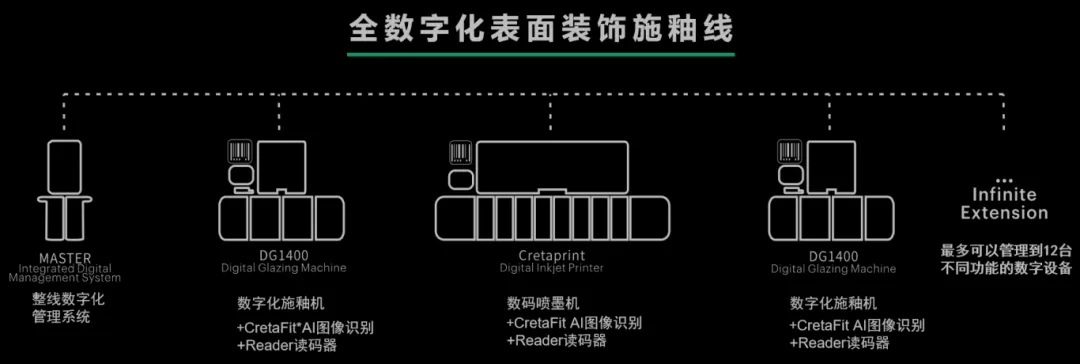

At the conference, Mr. Cheng Tao, Chairman and General Manager of DPI Cretaprint, delivered a speech on behalf of the brand. He not only launched the fully digital surface decoration glazing line but also introduced a comprehensive product matrix covering "management - glazing - printing - collaboration" with functional upgrades. Tailored specifically for the industry, this end-to-end industrial digital printing solution deeply aligns with the sector's core demands of "cost reduction & efficiency improvement, green transformation, and flexible production", providing ceramic enterprises with integrated intelligent solutions ranging from single-point technology to full-production-line intelligence.

President & GM of DPI, Mr. Tao Cheng

Full-Process Intelligent Collaboration: Building a Closed-Loop Digital Production Line

Centered on the MASTER Total-Line Digital Management System and SYNC Digital Synchronization System, a seamless collaborative system from design to finished product output has been established:

• Industry 4.0 Compatibility: Through Modbus protocol integration with third-party SCADA/PLC systems, it enables intelligent management such as equipment monitoring, ink volume control, and product traceability, empowering the construction of digital factories.

• Multi-Equipment Collaborative Upgrade: The MASTER system enables centralized management of multiple printing devices, coordinating pattern uploads, task scheduling, and data integration. The SYNC system, on the other hand, focuses on precise synchronization between two printing devices, breaking down barriers of independent equipment operation and ensuring a smooth and efficient production process.

*CretaFit: AI vision system for tile printing position adjustment.

Digital Glazing: Precise and Controllable, Redefining Glazing Standards

As a key component of the digital decoration line, the DG1400 Digital Glazing Machine achieves a leap from "traditional pouring glazing" to "precision glazing":

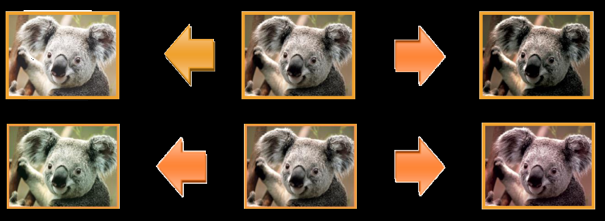

• AI-Powered Alignment: Integrated with the CretaFit AI vision system, it accurately identifies tile positions and embossed textures at the feeding stage, enabling real-time graphic translation and rotation adjustments. Millimeter-level positioning printing is achieved without downtime, avoiding overprinting and ink waste while significantly improving production efficiency.

• High-Speed and Wide Compatibility: With a glazing width of 1340mm, it accommodates tiles with thicknesses ranging from 6mm to 50mm, covering the specifications of mainstream ceramic products.

• High-Precision Control Upgrade: Through intelligent formula management and micro-level droplet control, linear adjustment of glaze thickness is realized. Compared with traditional processes, glaze consumption is significantly reduced. Equipped with the exclusive DPI-D10 printhead, it cuts down on material waste and production costs.

• Multi-Scenario Adaptability: Compatible with water-based and solvent-based glazes, it flexibly achieves diverse decorative effects (flat, three-dimensional, etc.), solving the industry pain points of "uneven application and limited options" in traditional glazing.

Comprehensive Product Matrix: Meeting Diverse Production Needs

Adhering to the concepts of modularity and versatility, DPI Cretaprint offers a full-scenario product portfolio to meet different production capacity and process requirements:

• Based on an enterprise's production scale and product type, it allows flexible combination of equipment such as digital glazing machines and digital inkjet printers, adapting to both small-batch customization and large-scale production scenarios.

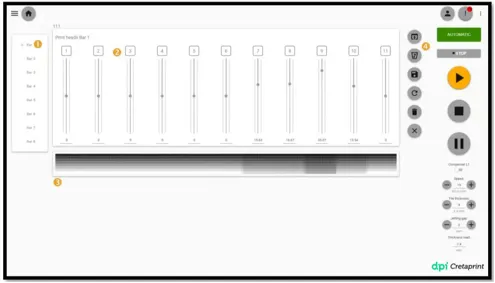

• Equipped with a multi-language intelligent touch interface, it supports online color adjustment, nozzle compensation, and ID printing traceability. The intuitive operation reduces reliance on manual labor.

6th-Generation Equipment Upgrade: Smart Connectivity Drives Efficiency Leap

With "end-to-end data interconnection" as its core highlight, it reshapes the intelligent collaboration efficiency of production lines:

• Full Configuration Compatibility: It inherits the mature technologies and functional configurations of the 5th-generation models and is compatible with mainstream printheads such as Dimatix StarFire 1024, Seiko RC536, and ED5.

• End-to-End Smart Linkage: It supports intelligent interconnection with upstream and downstream equipment in the production line, enabling automatic process handover. Combined with the "one tile, one code" traceability function, it achieves full visibility and controllability of the production process.

• Software Function Iteration: The newly added AI intelligent color mixing TAS system supports unified density adjustment of all color channels and precise optimization of single-channel tones. Combined with intelligent density compensation technology, it alleviates color differences at nozzle junctions, ensuring smoother color transitions.

Adjust the hue and density of existing jobs via the AI-powered TAS Smart Color Mixing System.

Intelligent Density Compensation optimizes the performance of printhead joints and mitigates color differences at the junctions.

Representatives from participating enterprises conducted in-depth discussions on issues such as technical adaptability, production capacity improvement potential, and implementation costs. DPI Cretaprint's industrial digital printing solution directly addresses traditional production pain points. Its core design of "full-process collaboration + modular configuration" not only meets current practical production needs but also reserves sufficient space for enterprises' future production capacity upgrades.

As a global technology enterprise deeply engaged in the field of industrial digital printing equipment, DPI Cretaprint has always taken "empowering industrial upgrading and driving technological innovation" as its mission, establishing a full-chain service system covering R&D, production, sales, and service:

• Profound Technological Accumulation: With 15 years of dedicated R&D in ceramic digital decoration technology, it has delivered over 2,000 sets of equipment cumulatively, with business presence in more than 30 countries and regions worldwide. The stability and reliability of its equipment have gained wide recognition in the industry.

• Global Service Network: It has established subsidiaries and offices in multiple countries and regions including Spain, India, Turkey, Morocco, Egypt, Indonesia, and Bangladesh, providing 24/7 Chinese-English bilingual technical support to ensure the efficient operation of equipment throughout its life cycle.

• Diversified Full-Scenario Solutions: Beyond the ceramic industry, DPI also provides customized digital printing solutions for textile printing, packaging, and other fields, achieving comprehensive coverage of digital printing application scenarios.

From technological innovation to industrial ecosystem co-construction, DPI Cretaprint has always kept pace with the high-quality development of the ceramic industry. The sharing of new technologies in the building materials field at this conference is not only a demonstration of the brand's core strength but also a strong driver for the digital transformation of the ceramic industry.

In the future, DPI Cretaprint will continue to deepen R&D in digital and intelligent technologies. With more forward-looking product iterations and a more comprehensive service system, it will provide global users with "precise, efficient, and flexible" industrial digital printing solutions. It is committed to helping Foshan ceramics and even the global ceramic industry break through traditional bottlenecks and jointly paint a new blueprint for the high-quality development of the industry!

EN

EN CN

CN ES

ES

LinkedIn

LinkedIn  Youtube

Youtube