Building Material

Textile

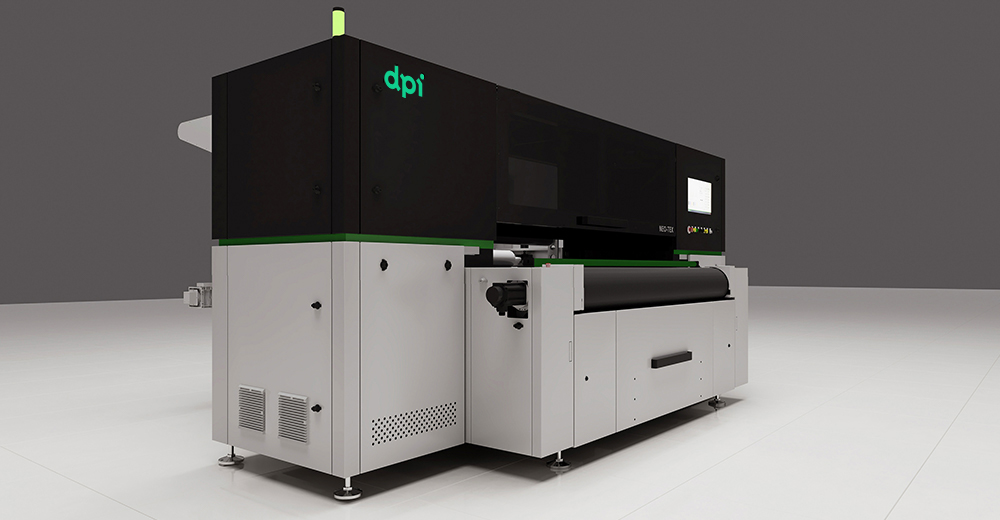

Digital Inkjet Printer

Textile

Pigment Ink

Reactive Ink

Disperse Ink

Acid Ink

Sublimation Ink

Textile

EN

EN CN

CN ES

ES

LinkedIn

LinkedIn  Youtube

Youtube